You can get caught up on the story here:

http://www.stagboatworks.com/?p=865" onclick="window.open(this.href);return false;

And we will jump in with both feet to the current update:

Long gap between posts, and only those who've done big refits on fiberglass hulls will see what really went on. Suffice it to say the white coating of dust on EVERYTHING is what's been taking several hours on several days, and little visible change.

Basically there's been about 50 lbs of fiberglass, paint, and gelcoat removed in prep for bonding the sole in. Tyvek suit, ski goggles, gloves, duct tape, respirator, and some misery. Those who know, know.

On the much brighter side, a shipment or two of stuff has shown up.

PSS dripless shaft seal. Washington based company, and a dry bilge:

Fresh full length cutlass bearings:

And through an epic show of benevolence and kindness, Darrin sent me his spare rudder from his original Salty Pup. He's had a larger version made that ate up some top end speed but has nice characteristics, so this one might get modified over time, but you can't make changes until you know the performance of the original. A huge thanks go to Darrin for this rudder and all the help he's provided through the build so far.

The fight for a tank went poorly at first. Was planning on custom tanks, but that was insanely expensive. Next up, looked at Moeller PEX tanks, which I'd used on previous builds. Mediocre price wise, but couldn't get enough gallonage in the boat for the sizes of the holes they could go in. Definitely didn't want to go above decks either. Then looked for used plastic, and it was an okay option, minus the $200 shipping charge.

The option I went with, luckily, was local. A welder I used in the past for some other work happened to have a couple tanks sitting on a shelf, so we went to work. First, the bow tank from another boat just needed a little length taken off, and it fit like a champ:

This fit really well in both height and between the V forward. 53 gallons down.

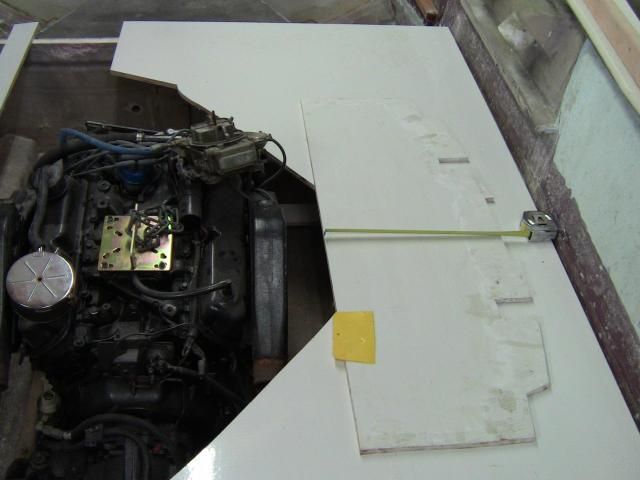

Then he also had a 46 gallon belly tank. Of course there's an engine there that precludes the belly tank idea. However, we took the tank, split it in half, and he welded up new sides where the center line used to be, and voila, 2 side tanks. Here's one in place:

Boom, almost 100 gallons of capacity, all under the sole, all in metal tanks. This should work out both from a clear deck standpoint and a low/balanced weight perspective.

Yes, there's a ton of dust in there. You should see the joint when I'm grinding...

My hope is the last of the grinding will be small. Gonna stick in the 1.5" x 2" cleats along the hull sides to support the sole, glassed in place and wrapped to the hull, then rig the drivetrain, followed by dropping in the sole. Let's hope the wife gives me some quality time to get it done.

E